How MB JWB Varlator Reducer can help the industrial sector Industrial machinery and drive systems. Today, the very same advantages are proof of this revolutionary Edge technology as already well-established in being at top data solution and leading to bring innovative features benefiting from both agility increase & performance enhancement. This comprehensive guide will take you on an in-depth look into how these mechanisms work, where they can be implemented across different business domains, and the key steps to ensure that maximum benefits are reaped.

MB JWB Varlator Reducers Increase Productivity | How?

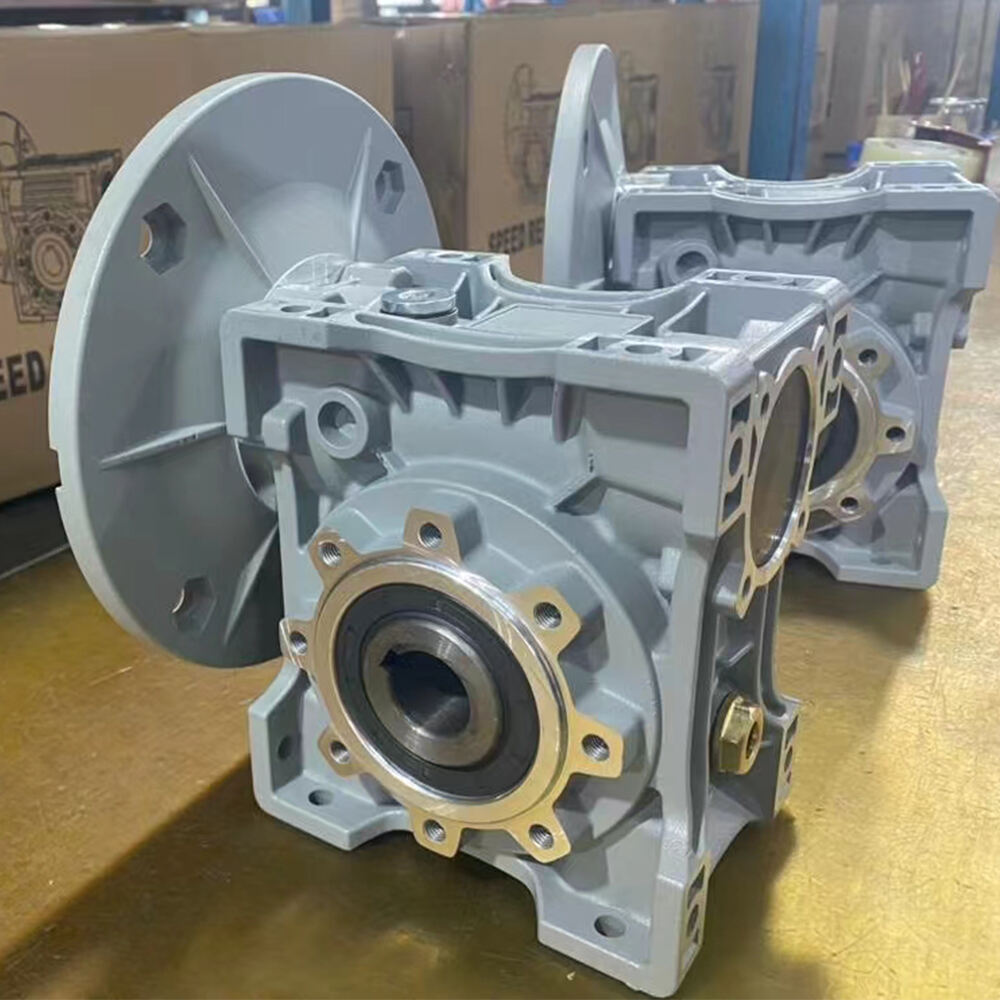

One of the key differentiators for MB JWB Varlator reducers is precise speed control, which up to now was only possible with traditional gear-based reducer. Through variable diameter pulley system that adjusts to the load, these reducers allow machines to run in top speed (reduces energy wastage) with increased overall efficiency of the entire system. Figure 3: Varlator reducers that achieve a balance between speed and torque While varlator reducers contribute greatly to increased productivity, they also help in reducing overall costs over the long run.

What Is The Science Behind MB JWB Varlator Technology

Built around a pair of variable sheaves connected by belt, MB JWB Varlator technology is an advanced design. One of the sheaves is stationary and other spaces its diameter due to load variations according with hydraulic or mechanical actuators. Normally this happens via sensors, which provide information that is evaluated by a control unit and the speed of travel can be adjusted continually ensuring power transmission always remains stable. This contributes to less energy use, lower component wear and an increased overall lifetime of the system.

MB JWB Varactor Reducers: Case Studies

The success stories of MB JWBVarlator Reducers being utilized in industries such as manufacturing, mining and material handling, are testament to its practical utility. One large-scale mine, for example, saw a 25 per cent decrease in energy costs within six months of installing the new reducers. Likewise, in an automobile assembly line using MB JWB Varlator technology increased the precision of robotic arm control resulting higher efficiency and decrementing maintenance downtime. This success stories are proof positive of the depth and breadth to which these reducers have been utilized in a variety industrial environments.

How to correctly Install MB JWB Variators]]

To get the most of your MB JWB Varlator reducers some good preparation is optimized suitable for assembly008 Sizing is critical to ensure that the capacity of the reducer meets or exceeds what is needed on machine. Furthermore, alignment of the pulleys and belt tension on that is required to ensure there will be no slippage between both & power transfer efficiency. Continuous monitoring and maintenance, belt wear inspections, as well as pulley checks are all necessary to maintain a level of performance. With those real-time data supports, this will help the reducer to be integrated with a smart control system (like BMS)/ or an optimizer so that it can adjust more efficiently.

Find Energy Savings with MB JWB Varlator Reducers In Your Operation

The use of MB JWB Varlator reducers in industrial systems not only saves energy, but also controls the ratio between machine speed and torque to prevent underloading or overloading waste. In addition, their adaptability also reduces the requirement for frequent start-stop cycles- a major energy loss in several processes. So, they not only bring financial benefits but also come in as environment-friendly reducer by aligning with sustainability goals and carbon footprints. MB JWB Varlator Reductions: For companies looking to improve production and save money on energy, the reducers from MB JWB Varlators are an intriguing answer.

To sum MB JWB Varlator the synthesis, in fact drive technology innovations leading to improved efficiency, productivity and ultimately energy savings. Backed by empirical evidence of their scientifically-based construction, as well as successful trials in actual operating conditions and integration instructions that are very easy to comprehend; these transmissions is the best companion for modern-age industries consistently at seeking an upper hand.

EN

EN

AR

AR

CS

CS

NL

NL

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

MS

MS

SW

SW

BE

BE

AZ

AZ

KA

KA

UR

UR

BN

BN

CEB

CEB

EO

EO

GU

GU

KM

KM

MN

MN

MY

MY

KK

KK

TG

TG

UZ

UZ

KY

KY

XH

XH