Use of Worm Reducer Gearboxes in Industries

Worm reducer gearboxes are important in boosting machine effectiveness across multiple sectors. High torque gearboxes are generally used in heavy-duty industries like manufacturing, transportation, and construction. This is where we can access the rather evident reasons behind why worm reducer gearboxes are so advantageous to have in these industrial scenarios.

Improving Machine Performance with Worm Reducer Gearboxes

It is necessary for machines to operate properly, so the worm reducer gearbox needs to be used. IntroductionThese gearboxes are great at transferring power and torque from one machine to the other. This feature allows the smooth process of heavy-duty machinery even under burdensome loads among other functions.

Worm reducer gearboxes are a perfect choise for demanding working situations, thanks to manufacturing from top quality material the gearbox is strong and timeproof. On top of that, they are created to be easy maintenance and repair keeping your downtime short. They are used in many places for multiple purposes, from needs like belt conveyor roller or conveying the heavy loads to lift a crane. In addition, they are essential in improving the productivity of an array manufacturing machinery.

Worm reducer gearboxes serve the purpose of transferring power and torque flawlessly between different machines, which is one standout advantage. This effectiveness not only enhances the performance of equipment, but also aids in energy preservation and long-term savings.

Worm reducer gearboxes are famous for their reliability and affordable price range which is the reason why they deliver continuous performance throughout the years. These gearboxes are a cost-effective alternative by reducing maintenance and repair costs associated over long periods. In addition, their high efficiency helps to reduce energy consumption and contributes more savings in the operational phase.

Companies who are focused on optimizing productivity, efficiency and profitability will benefit from the superior performance of worm reducer gearboxes with handling heavier loads. These gearboxes improve productivity and increase revenue generation for industrial applications by minimizing downtime, enhancing machine operations.

A new age in infrastructure - Mechanism and Versatility Across Industries

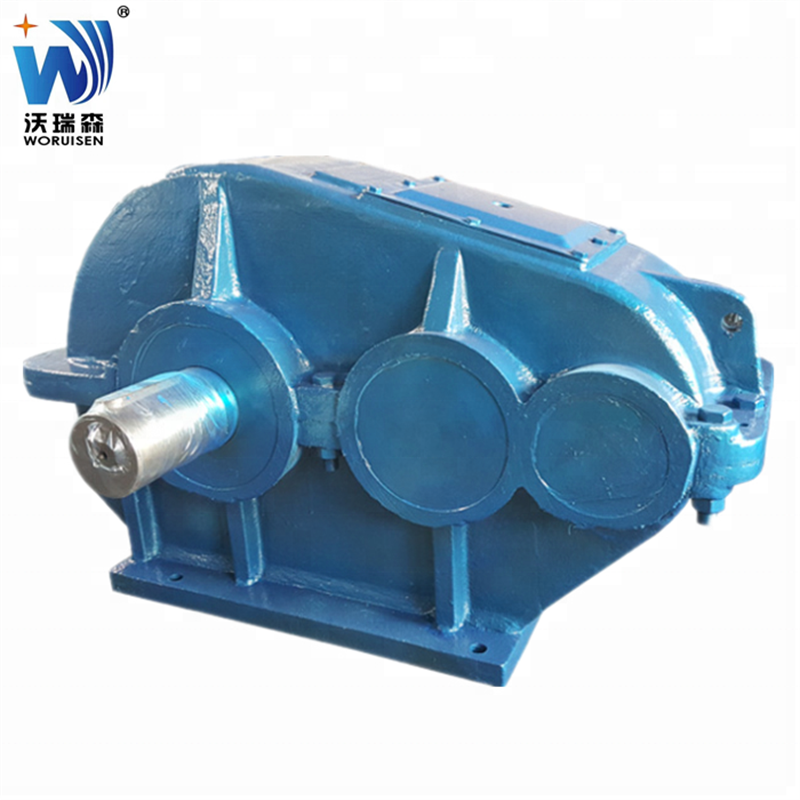

Worm reducer gearboxes, also known as worm gear operated motor and gearbox systems work on the principle of a worm wheel engaging with a spiral screw or straight toothed helical angle-cut cylindrical lined up close to perpendicular orientation. These features make them perfect for the heavy-duty machinery of various industrial sectors, improving machine performance and load handling abilities.

Summing Up - Overall, worm reducer gearboxes are fundamental to a variety of industries and significantly help in extremely optimized machine performance auto-efficiency thus saving energy element while driving cost factor. Industries dependent on heavy-duty machinery not only get multifaceted benefits from construction tractors but also gains adaptability for their professionals and this why it considered as a strategic investment.