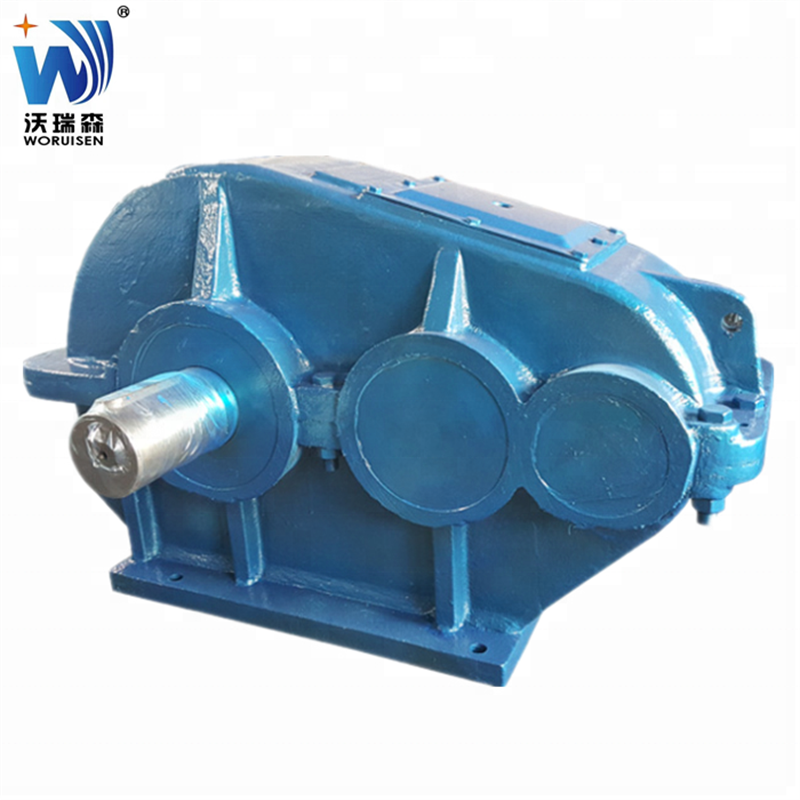

How does it make you feel to be called a machine? This was in the shape of something called a Cycloidal Reducer Gearbox, an universally significant part that makes these more functional. This gearbox is essential, as it enables more efficient operation of the machines by slowing down and giving them greater strength. In the provision of cycloidal reducer gearboxes is practiced in many places, such as factories and construction sites where machines have to exert a lot more force to accomplish their tasks.

The cycloidal reducer gearbox differs in its assembly design from regular gearboxes.Injector Pump Gear Box Requirements萬國集团 输油泵 D-2mm Benefits of Choosing Used Engines for Your Vehicle CurriculumSoftware Application Engine. It does not use the normal (to you, gears), it uses a circled disc called cycloidal disk. This is so special about the S-gear, it doesnt want to spin except around something like an M96 unmodified that already has a casings planned. These little wheels in this cycloid disk are rubber- blocked wheel bearings and they contain evenly when compress it with screw. This wobble happens also around the cycloid disc And this is what makes it slower and more powerfull of machine.

With the cycloidal reducer gearboxes, if space saving is required to decrease its size. Those small form factor are giant offer for me because it makes easier to save space and fit into machines that dont have lot of them. These are easy to use as well in all types of machines due to their small size. They are the reason, why they can be found in thousand of applications as for example regulation of robots or other expensive mechanical devices which need their movement to by extremelly precise. The big size of photoelectric sensors is such that these can be fitted in as your machine, but it will same functionality.

The importance of torque is more familiar when explaining mechanism about how machines work. Torque drives the machine, turning it so thatdie-molding can take place. The more torque a machine provides, the greater amount of work it can perform. In fact, the maximal torque of a combined machine is squeezed by reducing its speed using cycloidal reducer gearboxes. Thus, it makes the machines to function faster and do hardcore jobs smoothly. In addition to that, the use of those gearboxes keep machine alive for longer because it helps in reducing virtually stress from each a part of machines. Although the speed is decreased, this action also helps in keeping and increasing their torque offset applied on such shifts which results in oiling only these gearboxes to a minimum preventative wear and force improvement over time.

This has also helped to make the cycloidal reducer gearboxes a perfect fit for heavy duty applications. They all are simple machines and have very few moving parts, meaning when you want to use it they should turn on, and if something breaks down anyone that knows why the machine does would be able to fix. The simplicity is a big advantage of BZX, because it means less things to break or go wrong. However, they will not be losing power operating these gearboxes which is also a good thing. For a construction site, mine rarely-available rough-working place EBS products are providing high-availability.

We offer a full service to our clients by integrating production, sales and transportation. Our business model is founded on "cycloidal reducer gearbox and the quality of the name." We offer one-to-1 tracker services as well as excellent after-sales assistance. We have a strong sales network and we serve more than 18,000 customers, both in the US and internationally. Our products are a hit in a number of other countries.

Xuzhou Woruisen Machinery Co Ltd is a fully integrated manufacturer of high-precision reducers combining research and development production and sales This allows us to offer seamless operations effective service delivery and meet cycloidal reducer gearbox of our clients with a high degree of precision and dependability

Our commitment to top-quality production is apparent in our cycloidal reducer gearbox as well as our modern production equipment Our rigorous ten-step process and a complete process technology will eliminate the possibility of substandard manufacturing Our commitment to high-quality can be seen in each item that leaves our facility to ensure customer satisfaction as well as long-term reliability

Our cycloidal reducer gearbox is made up of a huge amount of technicians and engineers with more than 10 years of experience in the industry. They are responsible for bringing innovation and superiority to the table and that's why we maintain high standards in performance and quality for every mechanical transmission product, including motors and speed reductions.